Specialities from the world centre

Maranello is famous for its red sports cars and Geneva is the Mecca for watch enthusiasts – but the products from Tuttlingen are usually only known to specialists. Over 400 companies produce world-renowned instruments and devices in the global centre of the medical industry. Tweezers, implants and endoscopes: the expertise in the medical industry has grown over time and is passed down from one generation to the next. The company HG-Micro-Instrumente GmbH & Co. KG from Wurmlingen, near Tuttlingen, is one of these specialists. The team, led by managing director and production manager Christoph Götz, produces forceps, ear tweezers and other medical instruments. In addition to skilled manual work, the company relies on modern CNC machining centres and tool systems. For milling tweezers, HG-Micro-Instrumente GmbH & Co. KG uses tool systems from Paul Horn GmbH and hydraulic chucks from Schunk.

"We once had a complaint because the forceps were four grams too light," jokes Christoph Götz as he talks about his experience and continues: "Almost everything is certified when it comes to surgical instruments. Even the slightest deviation from the target parameters is not acceptable, even if tweezers are made of titanium to reduce weight." Tolerances of a few microns are the order of the day in the production of medical instruments. HG-Micro-Instrumente GmbH & Co. KG produces the products on a contract basis for the big players in the medical industry according to drawings and customer requirements. 90 per cent of the instruments are titanium. "We process steels such as 1.4021 into ear tweezers," explains Götz.

Quality was not good enough

The carbide blanks for the tweezers arrive as turned parts. Götz and his team use a Hermle C22U machining centre to produce both halves of the tweezers from carbide blanks. The two halves are laser welded together in a subsequent process. "We used to buy in the halves already machined. However, the quality was no longer good enough for us. We were also inconvenienced by the long delivery times," says Götz. The company therefore switched the production processes to complete machining. To do this, Götz looked for an appropriate tool solution. It was not just the insert that was important, but the entire system from the insert to the spindle interface. Due to the sometimes long tool overhang and the high surface finish required, the tool system must be vibration-damped to avoid chatter marks.

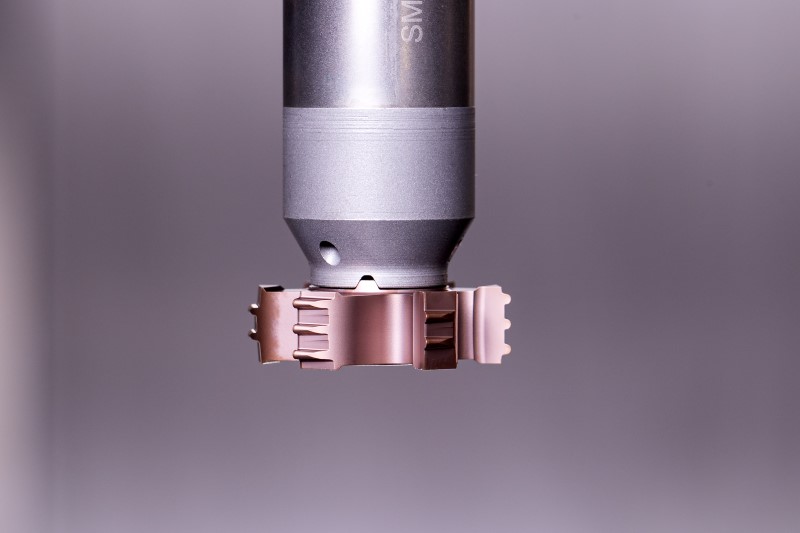

Together with HORN applications engineer Stefan Minder, Götz found the appropriate tool solution with HORN's circular interpolation milling system. The milling system performs three important processes: milling the hollow groove, milling the gear teeth of the tweezer tip and milling the handle pattern for flat-handled tweezers. A six-edged type 632 full-radius insert is used for milling the chamfer, which serves to reduce weight. The tool has a diameter of 30 mm (1.181") and mills the 3 mm (0.118") deep chamfer in two cuts. "The tool demonstrated high milling performance right from the start. We just had to tweak the machining parameters a little here and there to achieve the best possible surface quality," says Minder.

Cut distribution

A type 628 insert with six cutting edges is used for milling the handle pattern and the serrations of the tweezer tip. The individual insert edges are ground offset to each other. The six-edged insert therefore acts like a three-edged insert during the milling process. The advantage of this cut distribution is that fine serrations, for example, can be milled without high cutting pressure. The fine serrations must be present on the tweezer tip. In one milling pass, the 7 mm wide insert mills 17 teeth to a depth of 0.35 mm. In addition, the milled serrations must be highly precise. In use, the serrations on the two halves of the tweezers must mesh precisely. This principle of cut distribution is also used when milling the handle pattern.

The optimised cutting edge geometry in conjunction with the IG35 coating ensures high productivity and process reliability when machining titanium. With a coating thickness of just 0.003 mm (0.0001") and a maximum operating temperature of around 1,100 degrees Celsius (2,012 degrees Fahrenheit), the tool achieves on average twice the service life of conventional coatings. HORN coats the tools in-house in its own HiPIMS coating systems. In addition to high cutting performance, this enables fast delivery of the tools.

HORN circular interpolation milling system

HORN's circular interpolation milling system offers the user a number of advantages: It is fast, reliable and achieves good surface results. The tool, which is guided on a helical path, plunges into the material either at a steep or a very shallow angle. It allows high-quality threads, for example, to be produced reproducibly. Compared to machining larger diameters with indexable inserts or smaller diameters with solid carbide milling cutters, circular milling cutters are generally more economical. They have a wide range of applications, including machining steel, special steels, titanium, aluminium and special alloys. The precision tools are particularly suitable for slot milling, helical milling, thread milling, T-slot milling, profile milling and gear milling. However, they are also highly effective in special applications such as milling sealing grooves or connecting rod machining.

Stable overall system

Götz relies on the Schunk TENDO hydraulic clamping system for securing the milling tool. TENDO has been a byword for precise clamping of shank tools for decades. Thanks to continuous further development, this pioneering clamping technology meets the constantly increasing requirements of demanding, universal precision machining. TENDO is suitable for all common shank types. The wide range of products offers the appropriate solution for almost every application. The runout and repeatability of the clamping system is around 0.003 mm (0.0001"). The excellent vibration damping is particularly advantageous with long tool overhangs.

The combination of the insert, solid carbide tool shank and hydraulic chuck performs well in HG-

Micro-Instrumente applications. "We have mastered the milling process and are very satisfied with the result. Furthermore, HORN's service and technical advice are of a very high standard," says Götz.

Extra HG-Micro-Instrumente GmbH

For over three decades, HG-Micro-Instrumente GmbH & Co. KG has been dedicated to the manufacture of high-quality surgical instruments, which are 100 per cent manufactured in Wurmlingen. A family-owned company, HG-Micro-Instrumente GmbH & Co. KG focuses on high quality, flexibility and reliability in every phase of production. Its expertise lies not only in the manufacture of surgical instruments, but also in CNC contract machining, where the team develops customised solutions for its customers. The company always strives to achieve a high level of customer satisfaction and makes no compromises when fulfilling exacting production requirements.