Application Stories

When theory becomes practice.

We use selected machining examples to demonstrate the use of

HORN tool solutions with our customers.

Emotions and craftmanship

With his company EBG-Instruments, hMarc Locher is breaking new ground, but also holding on to old traditions. For a current project, a Telecaster, 3D printed parts made of titanium and CVD diamond cutters are being used. Locher received support from Paul Horn GmbH for this project.

Further Application Stories

Präzise Verzahnung für die zielgerichtete Kühlung

Das Unternehmen Asch & Sebert hat einen Kühlmittelring entwickelt, bei dem sich die Kühlmitteldüsen automatisch der Werkzeuglänge anpassen. Dabei kommen Werkzeuge von HORN zum Einsatz.

Absolute precision in the battle for first place

For the 2025 race season, the Formula Student Team “DHBW Engineering” at Stuttgart University of Applied Sciences asked HORN for help in manufacturing components for the "eSleek25".

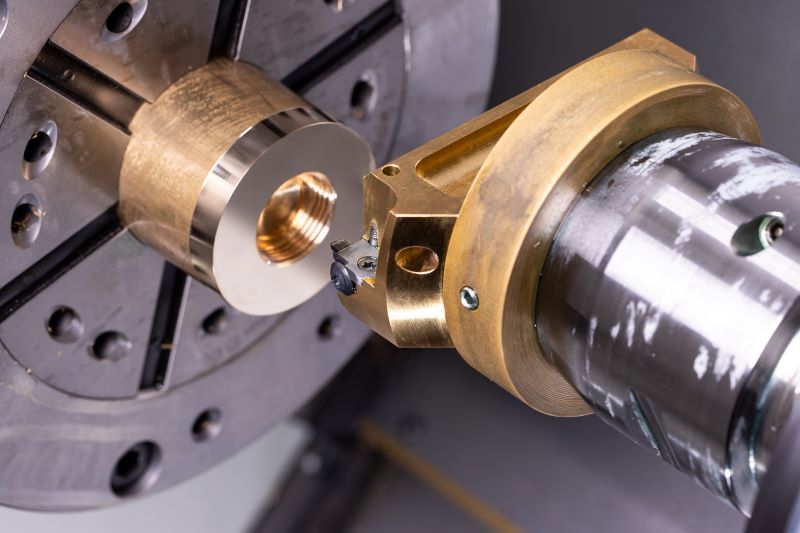

A new era of European space travel

Extremely tight tolerances, exotic materials and high component costs - nothing can go wrong in rocket science. The company ArianeGroup in Ottobrunn therefore relies on precision tools and HORN's technical expertise.

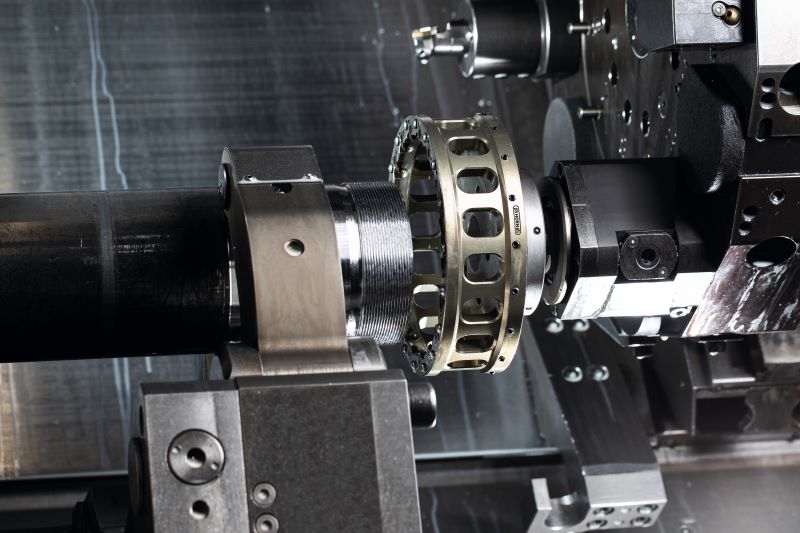

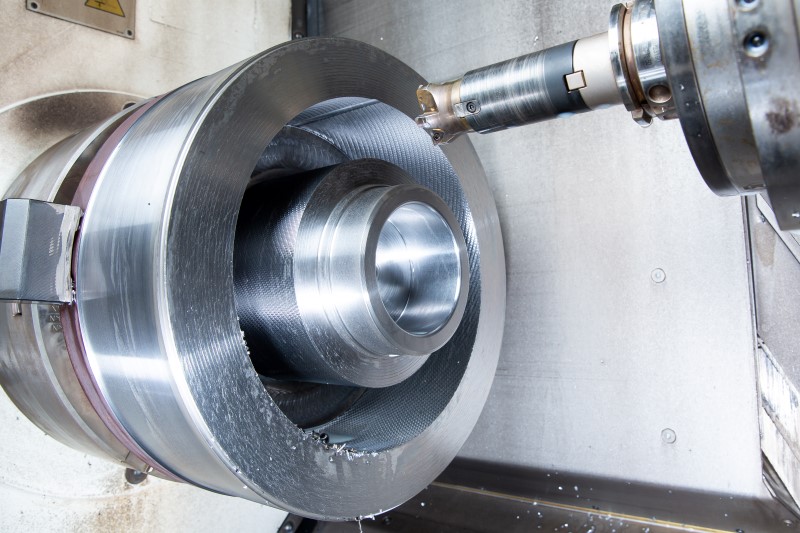

Threadcutting in seconds

For machining an external thread on a cylinder, the company Vremac from Apeldoorn switched to a special milling system from Paul Horn GmbH.

The perfect fitting with diamonds

To ensure the high quality of its products, the Belgian company RVB relies on HORN diamond tools for high-gloss surfaces for over 15 years.

Precision is a passion

Corcym has been relying on HORN tool solutions for over 15 years. “So far, no others have delivered anywhere near as convincing a performance as the HORN products,” says process engineer Davide Ricchiari.

Chipping problems solved

The metrology company was one of the users that was able to test the new Supermini in field trials. The field tests were the first milestones in HORN’s progress.

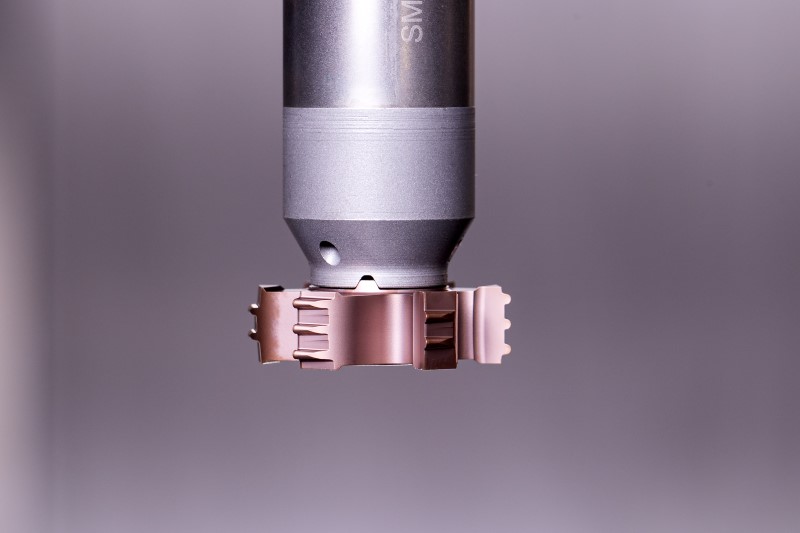

14 times faster – and even more potential

For 20 years, Bamann has relied on tools from Paul Horn GmbH in its production. The high-feed milling system DAH brought it success.

Specialities from the world centre

For milling tweezers, HG-Micro-Instrumente GmbH & Co. KG uses tool systems from Paul Horn GmbH. HORN's circular interpolation milling system offers the user a number of advantages.

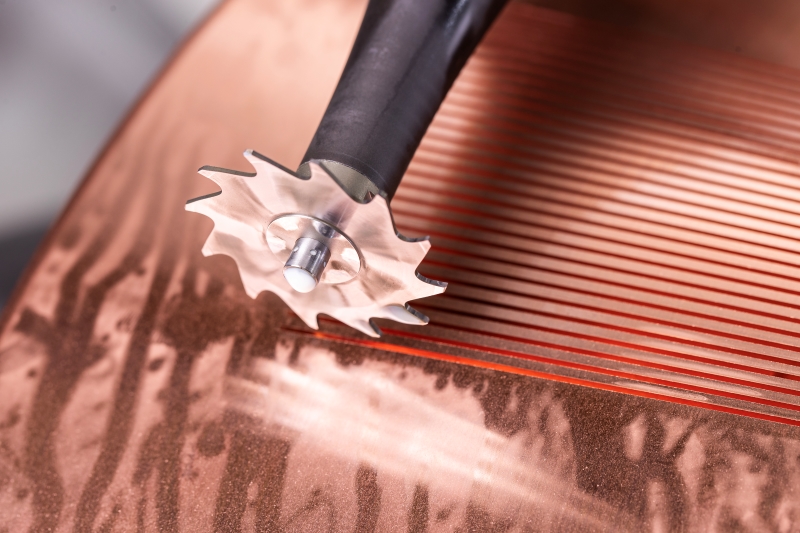

DOLCE VITA

For the production of its pasta maschines Imperia & Monferrina from Turin relies on Horn tool systems and on technical advice from Febametal, the Italian representative of the German tool specialist.

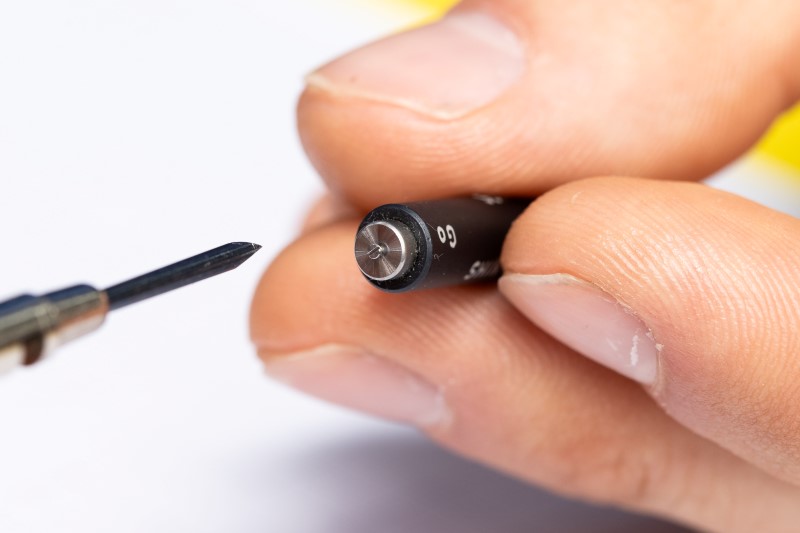

Micro screws for the watch industry

Aeschlimann relies on the Horn µ-Finish tool system for sliding-head turning of watch screws. Micromachinists are the main target market for this range of tools, which is based on the S274 system.

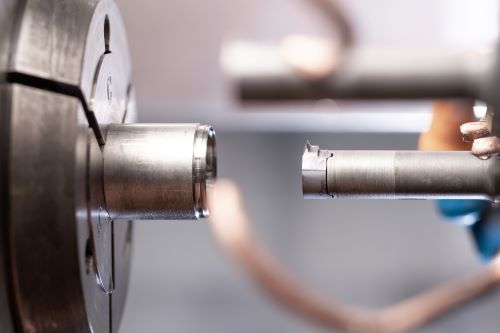

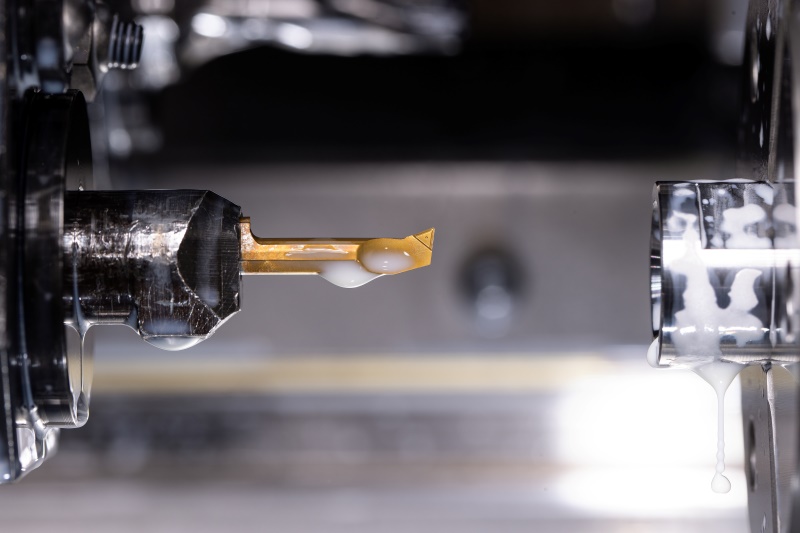

Chip control and micro-precision

For boring, the company RICH Praezision GmbH relies on the new generation of Horn Superminis with sintered chip breaking geometry. “With the new inserts, all chip problems during boring have virtually disappeared into thin air,” says Gottfried Rich.