DOLCE VITA

Italy is famous for its cuisine and authentic dishes, which are global favourites. Alongside pizza, it is the countless varieties of pasta that have conquered the world. No wonder that the machines used to make pasta also come from its home country. Imperia & Monferrina from Turin produces pasta machines that are found in factories, restaurants and households worldwide. "We have been working on the development of the perfect machine for almost 100 years," says Managing Director Enrico Ancona. For the production of the individual parts, the company relies on tool systems from Paul Horn GmbH and on technical advice from Febametal, the Italian representative of the German tool specialist.

The design of the classic pasta machine for the home kitchen has hardly changed since the 1950s. With the Imperia "Classica", the company set the standard for this type of machine. The principle is simple: the front rollers are used to press the pasta dough into a shallow, long sheet. The long sheet of dough is then moulded into the desired shape using an attachment. "The attachment is the heart of a pasta machine and where its quality is defined," says Ancona. Imperia also offers electric models for home and restaurant use. However, the basic principle remains the same.

Professional machines

With the La Monferrina brand, the company produces machines for professional use. La Monferrina has been part of the Imperia world since 2010. Under this brand name, the company produces machines for professional use. The machines are capable of producing pasta in all shapes and sizes on a large scale and are sold worldwide. Depending on machine type, a machine may combine mixing and kneading of the dough with subsequent moulding. The machines can also fill and seal ravioli in a matter of seconds. Special moulds are used to shape the pasta. Similar to injection moulding, the dough is compacted by an increasingly narrow insert, then pressed through the die at high pressure and cut to the desired length. The pressure and the outlet/slot of the mould determine the shape of the pasta produced.

"The precision of the individual components is very important to us, otherwise the pasta machine won't work," explains Production Manager Federico Marchese. In addition to shaping, the moulding rollers cut the pasta dough. To do this, the grooves of the rollers interlock. Before switching to HORN's tool systems in 2008, mechanical, cam-controlled automatic lathes of older design were used in production. "The production process was reliable, but retooling and tool changing were very time-consuming," says Marchese. To increase productivity, the company decided to take a big step and invest in modern Swiss-type lathes. In addition to the new machine technology, the tool concept also had to be revised. The old machines used specially ground tools, some of which were still made from HSS.

Two million rollers

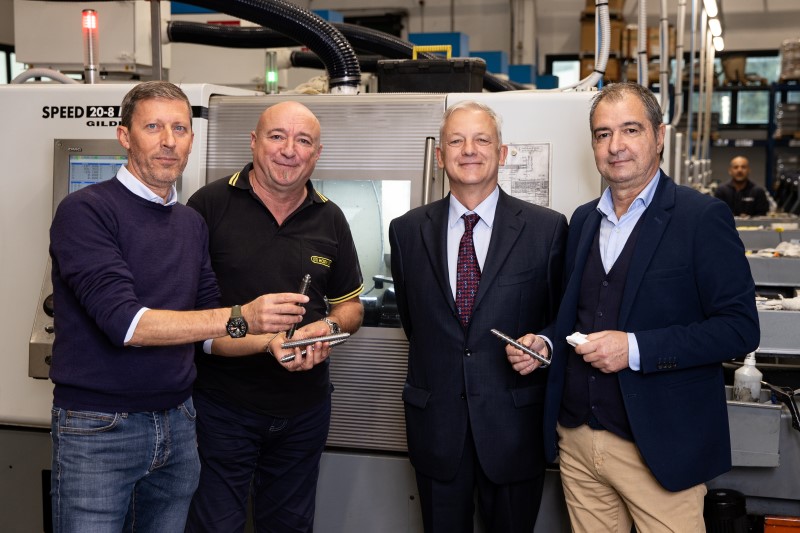

Febametal application engineer Andrea Panichi remembers: "Designing the tool concept was not easy. We had to prove that it was worth investing in cost-intensive special carbide tools." Panichi's efforts convinced those responsible at Imperia & Monferrina. In addition to higher productivity, the tool systems achieve a tool life that is in some cases 30 times longer than previously. Around two million of the pasta moulding rollers in diameters of 18 mm (0.709") and 14 mm (0.551") are produced each year on eight swiss-type turning machines. The company manufactures the rollers from stainless steel and carbon steel.

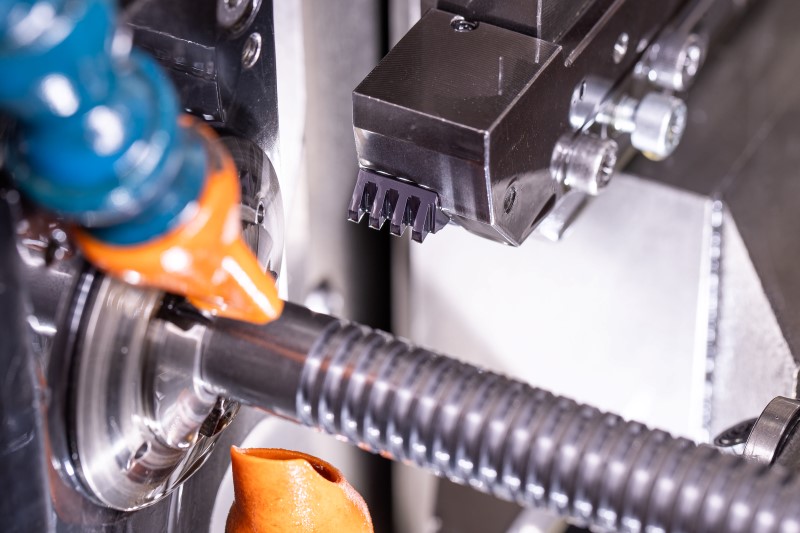

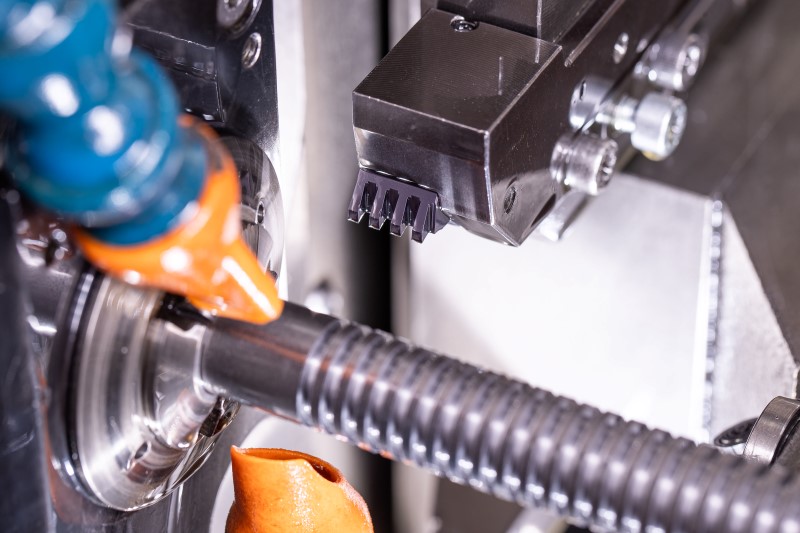

There is a special roller mould for each type of pasta. It incorporates grooves of different widths depending on the pasta type. A mould for wide pappardelle has fewer grooves on the shaft than one for thin spaghetti. Different HORN grooving systems are used. To achieve greater efficiency when turning the individual grooves, one tool is used to machine several grooves in one pass. The three-edged grooving system 315 is used. On the carbide blanks, which have a maximum cutting width of 15 mm (0.590"), several teeth can be ground at the same time. "The 315 system is very suitable for this, as the cutting depth of around 3 mm (0.118") is not too much. Furthermore, the tool does not need to be remeasured when turning the indexable insert, as its seat has a changeover accuracy in the range of a few microns," explains Panichi. During the grooving process, the tool produces up to four grooves in one pass. Another special feature is the burr-free grooves. "The grooves are sharp-edged, as their corners act like a kind of knife to cut the dough," says Marchese.

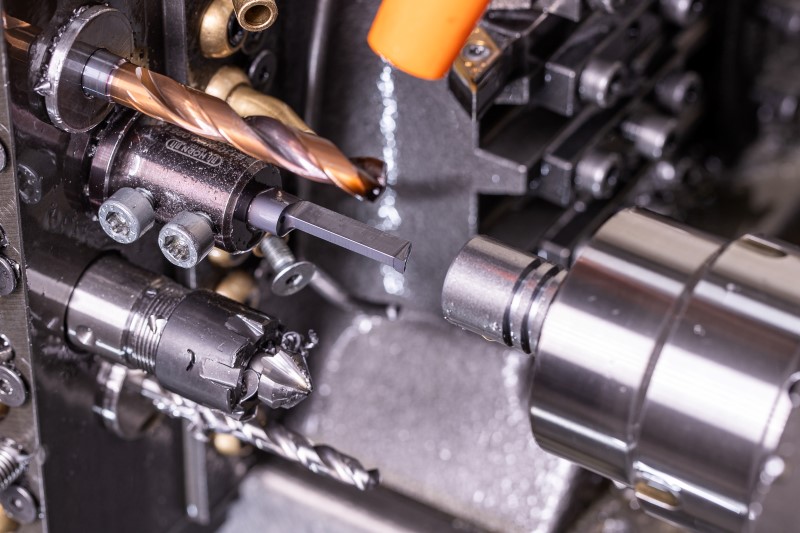

Slot broaching with Supermini

Each roller has two drive slots to transmit the torque of the manual force or an electric motor to the moulding rollers of the pasta machine. A Supermini N105 tool is used for broaching the 3 mm wide by 2 mm (0.079") deep slots. During the process, the machine positions the tool in front of the hole and starts broaching the slot, which is around 20 mm (0.787") long. The individual axial shaping strokes are divided into increments of 0.1 mm (0.004"). There is no need for a recess at the bottom of the groove, as the tool moves freely inside on a programmed path.

The process of slot broaching on the machine offers the user various advantages. Different slots, profiles, gears or guide slots can be produced. A single clamping is sufficient to produce the workpiece. This means that further machining steps or even investments such as broaching machines can be saved. Furthermore, complete machining helps to increase precision and boosts the productivity of machining processes.

The collaboration between the Italian pasta machine specialist Imperia & Monferrina, HORN and Febametal has been in place since 2008. "Since our big move from cam-type machines to modern CNC sliding-headstock automatic lathes, we have always received a great deal of support with the tooling. This has enabled us to increase the productivity of our machining processes enormously," says Managing Director Enrico Ancona.