Mastering processes: Whirling

The whirling method was invented by the German Karl Burgsmüller in 1942 and 80 years later, manufacturing industry still relies on the process as it offers significant advantages over conventional threading methods. However, tools have been continuously evolving during this time. In 2018, Horn introduced jet whirling, an internally cooled process, which represents a new milestone in whirling technology. Horn has demonstrated its expertise in the whirling process with this development.

Key advantages of whirling include high cutting rates, long threads with high surface quality, deep thread profiles, short chips, multi-threads and minimal tool load. However, despite these benefits, the user has to face various technical challenges. One important aspect are the materials used for bone screws, for example. The cutting edges of the whirling inserts are subjected to extremely high loads when machining titanium, stainless steels and other superalloys. To counteract cutting edge wear while maintaining the required high chip volume and short processing time, tool manufacturers need to constantly optimise the tools and processes used and develop them further.

Horn demonstrates its expertise in the area of thread machining with the jet whirling process. As part of a collaboration with W&F Werkzeugtechnik in Großbettlingen, experts from both companies have jointly developed a whirling system with an internal coolant supply. By cooling the cutting edges directly, this system enables long tool life to be achieved. What’s more, in conjunction with the stable whirling unit, the system achieves better surface quality on the workpiece and reduces the risk of chip build-up between the inserts. Surface quality is of major importance in the production of bone screws. Every groove or ridge can provide a breeding ground for germs.

Tight spaces

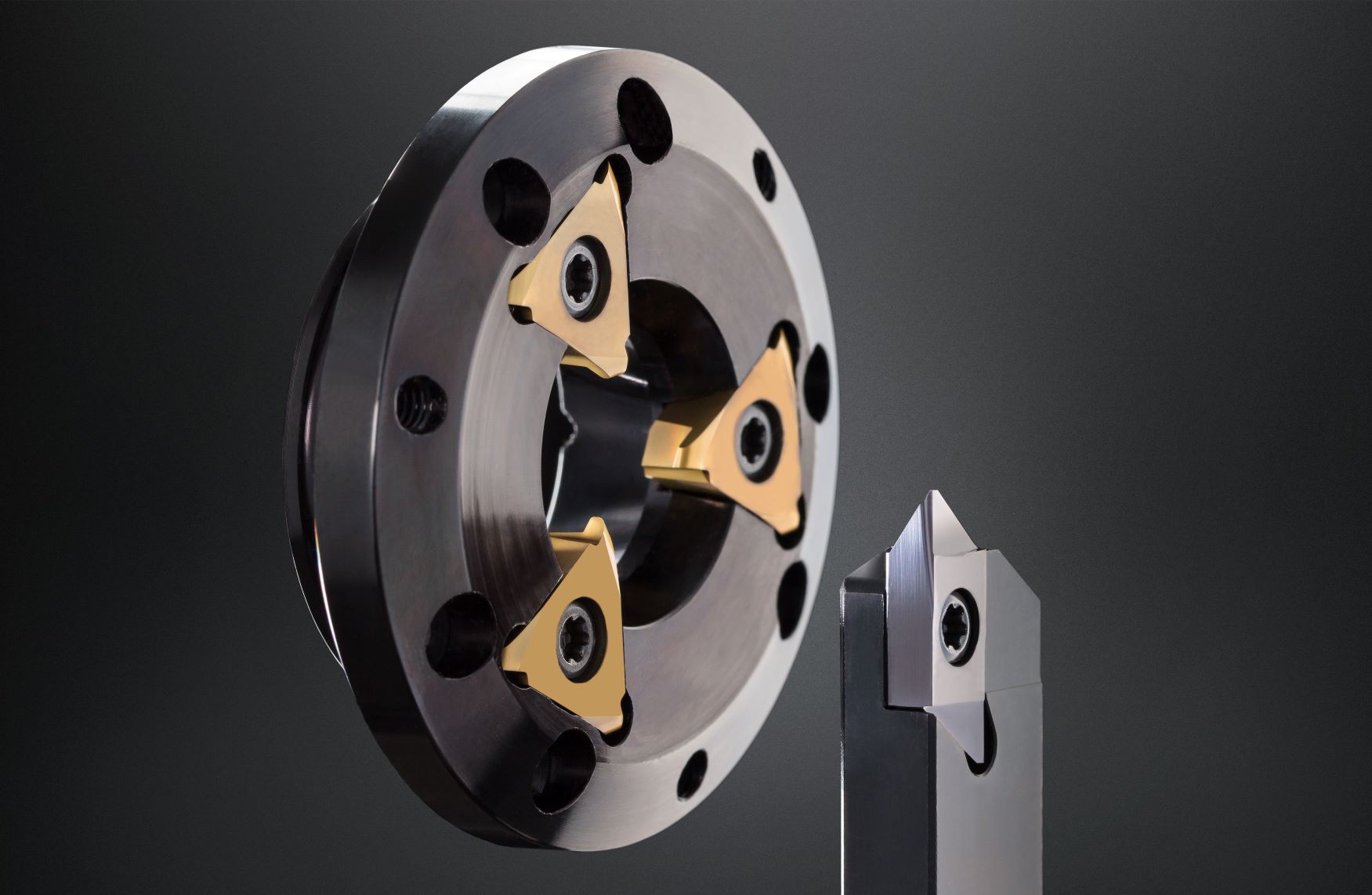

Swiss-type lathes are usually used for the production of precision screws. This is a very productive and space-saving machine technology. However, one challenge is the restricted space inside the machine. For this reason whirling units must be very easy to set up and use. Thanks to its face-and-taper contact system, the Horn whirling head boasts a high changeover accuracy and is easy to change with just three screws. It takes less than a minute to exchange the head on the whirling unit interface, which offers radial and axial run-out of 0.003 mm (0.0001"). The maximum speed is 8,000 rpm.

Horn is proud to present another technique in the form of high-speed (HS) whirling. This technology was established in collaboration with machine manufacturer Index-Traub. HS whirling boosts productivity significantly by performing the turning and whirling operations in parallel. With this technique, the speed is high enough for turning to be carried out prior to whirling. The turning tool, which is located upstream of the whirling tool, reduces the volume of material that would otherwise have to be removed by the whirling tool. This enables longer tool life to be achieved and improves surface quality. The whirling heads are very similar to conventional ones. The only difference lies in the geometry of the cutting inserts. Single-start and multi-start threads can be produced using just one cutter unit.

Horn offers further whirling technologies in addition to its jet and high-speed whirling solutions. Of these, the most universal technology is the standard whirling method. The whirling head can be connected to any whirling unit. For faster whirling head and cutting insert changeover away from the machine, Horn has developed a modular whirling system. Thanks to the precision interface, there is no need to readjust the whirling head once it has been removed from the machine. In addition, spacer rings make it possible to adapt the whirling tool to different interfaces. With Horn turbo whirling, high productivity is ensured. The cutting force distribution between the roughing, pre-finishing and finishing cutters reduces the load on the whirling tool’s inserts. As a result, the system offers faster process times and lower tool costs.