Chip control and micro-precision

For over 40 years, the brothers Wolfang and Gottfried Rich have relied on precision tools from HORN. As both a customer and supplier of Horn, RICH Praezision GmbH produces high-quality turned parts for various industries. For boring, the company relies on the new generation of Horn Superminis with sintered chip breaking geometry. “With the new inserts, all chip problems during boring have virtually disappeared into thin air,” says Gottfried Rich. The new tool is used for boring the body of the Horn SX interface.

RICH Praezision GmbH has been a supplier to Horn for several years. The company produces the body of the precision interface for the Horn tool system SX, which is a further development of the 42X type family. The cutter head is connected to the contact surface of the tool body via a stable, robust, yet highly precise thread. This interface offers several advantages: high stability due to the generous thread size, wide support due to the large contact surface and precise changeover accuracy in the µ range, which is always in the centre of the tolerance band. In addition, changing the cutter head is simple and user-friendly. The replaceable head system is mainly used for milling and skiving tools that are brazed onto a tool body made of tool steel.

“Manufacturing the tool holders was initially a major challenge. The precision that Horn requires is very high,” explains RICH production manager Wolfram Stiefel. RICH Praezision GmbH manufactures tens of thousands of parts of numerous types for Horn every year. Stiefel relies on Horn tools for producing Horn components. Critical features for the machining are, on one hand, the mating thread and, on the other, several very tight tolerances. In addition, the concentricity and axial run-out of the various contact surfaces are important.

Chipping problems

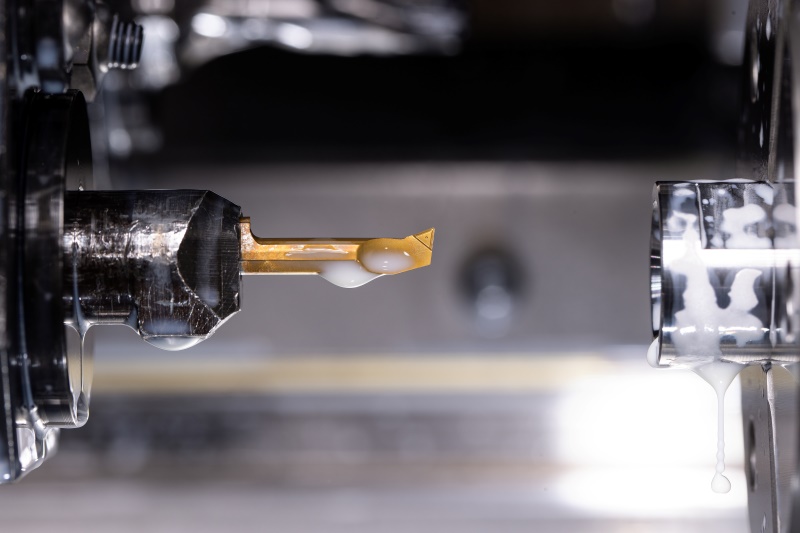

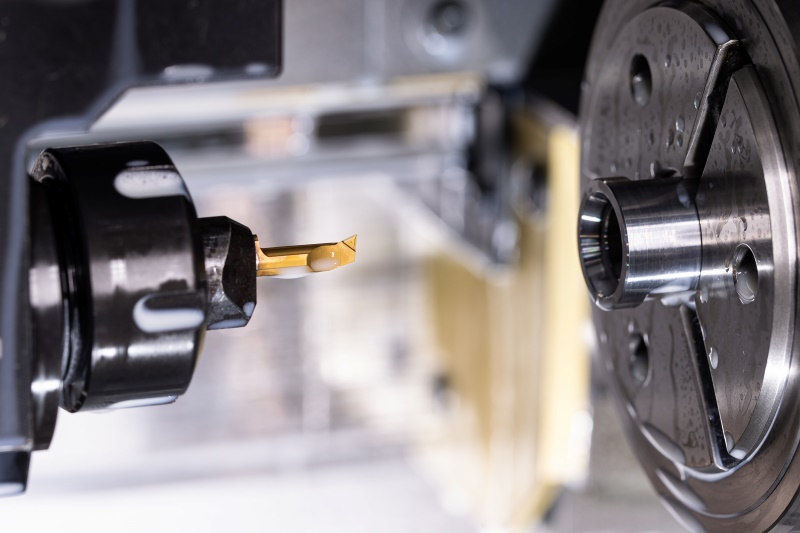

Several different Horn systems are used for turning the components. RICH generally uses the Supermini system for boring small diameters. In addition to a precision thread, a taper and an additional fit are used for centring the SX interface with µ-precision. A Supermini type 105 is used to turn the taper and the fit. “The turning process for achieving the very tight tolerances is stable. One problem we have always had when boring small diameters is long swarf that wraps around the tool. Everyone has this problem, irrespective of the tool manufacturer,” explains Wolfgang Rich.

With the new generation of the type 105 Supermini, Horn has solved the problem that otherwise only lasered or ground special cutting inserts could solve. “With the new Supermini type 105, Horn has succeeded in developing the world’s first universal boring tool with sintered chip breaking geometry for machining small diameters,” explains Horn technician Frank Blocher. The tool offers a high level of process reliability thanks to its excellent chip control. The cutting geometry extends far into the corner radius of the insert. This ensures good chip control even with small infeed settings. The geometry can be used universally for different material groups.

New Supermini generation in use

The advantages of the new system are evident. “The problem of tangled swarf was solved immediately. Whereas we had to manually remove ribbons from the tool with the previous system, the fine chips are barely visible in the swarf bin thanks to the new geometry,” says Wolfang Rich. Tool life is equivalent to that of the inserts without geometry. The same applies to the price of the new generation of inserts, which is almost equivalent to that of the comparable inserts without geometry.

High-precision thread milling

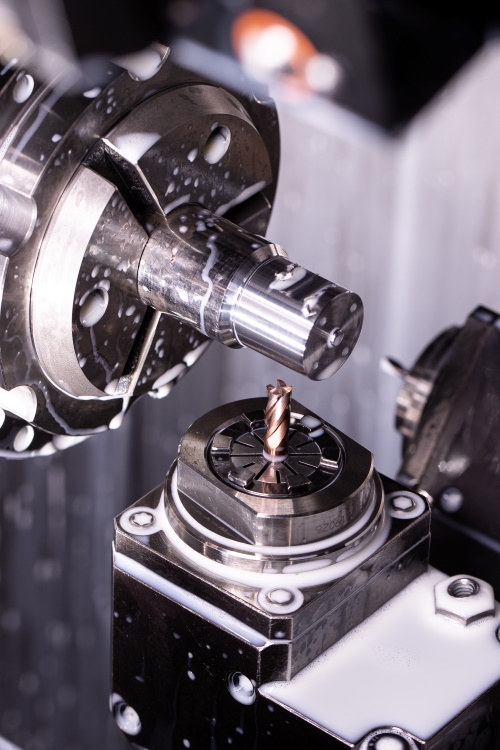

Depending on the diameter of the SX body, the Horn circular interpolation milling system or the DC solid carbide milling system is used for milling the internal thread. The inserts are precision ground as a special tool with the bespoke thread profile. The threads are milled in several infeeds. “The thread is checked using a plug gauge that Horn provided us with,” says Stiefel. Another type 306 circular milling cutter is used for milling an internal groove. Stiefel chose milling, as the process is more stable than turning due to the unfavourable length-to-diameter ratio. “The circular interpolation milling system with interchangeable cutter head or as a monoblock version can be customised precisely for such milling tasks,” explains Horn sales representative Frank Blocher.

Horn’s circular interpolation milling system offers the user a number of advantages: It is fast, reliable and achieves good surface finish. The tool, which is guided on a helical path, plunges into the material at a steep or a very shallow angle. This allows threads, for example, to be produced in reproducibly high quality. Compared to machining with indexable inserts for larger diameters or solid carbide milling cutters for smaller diameters, circular milling is generally more economical. Circular milling cutters have a wide range of applications. They machine steel, special steels, titanium, aluminium and special alloys. The precision tools are particularly suitable for groove milling, helical milling, thread milling, T-slot milling, profile milling and gear milling. They also perform well in special applications such as milling sealing grooves or connecting rod machining.

“The new generation of Superminis has shown us once again why we have been relying on precision tools from Tübingen for over 40 years. We are excited to see how the problem solvers from Horn will continue to support us in the future,” says Gottfried Rich.